Three Mile Island accident

2008/9 Schools Wikipedia Selection. Related subjects: Engineering

The Three Mile Island accident was the most significant accident in the history of the American commercial nuclear power generating industry. It resulted in the release of a significant amount of radioactivity, an estimated maximum of 13 million curies of noble gases (480 PBq), but under 20 curies (740 GBq) of the particularly hazardous iodine-131, to the environment. However, there are no immediate deaths or injuries to plant workers or members of the nearby community which can be attributed to the accident. Public reaction to the event was probably influenced by at least three factors: first, the release (a few weeks before the accident) of a popular movie called " The China Syndrome", concerning an accident at a nuclear reactor; secondly, what was felt to be a lack of official information in the initial phases of the accident; and lastly, many of the statements made by political and social activists long opposed to nuclear power. Whatever the sources of the local fear and outrage, public reaction to the event is judged by some epidemiologists to have induced stresses in the local population that could have caused adverse health effects.

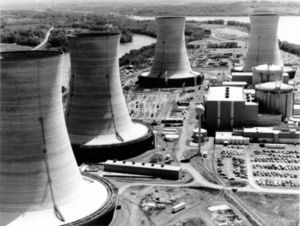

The accident began on Wednesday, March 28, 1979, and ultimately resulted in a partial core meltdown in Unit 2 of the nuclear power plant (a pressurized water reactor manufactured by Babcock & Wilcox) of the Three Mile Island Nuclear Generating Station in Dauphin County, Pennsylvania near Harrisburg.

Jack Herbein, Metropolitan Edison's then Vice President for Power Generation initially and erroneously called the accident "a normal aberration." The scope and complexity of this reactor accident became clear over the course of five days, as a number of agencies at the local, state and federal levels tried to solve the problem and decide whether the on-going accident required a full emergency evacuation of the local community, if not the entire area to the west/southwest. In the end, the reactor was brought under control, although full details of the accident were not discovered until much later.

Although 25,000 people lived within five miles (8 km) of the site at the time of the accident, no identifiable injuries due to radiation occurred, and a government report concluded that "There will either be no case of cancer or the number of cases will be so small that it will never be possible to detect them. The same conclusion applies to the other possible health effects."

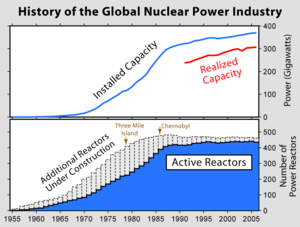

The accident was followed by essentially a 100% cessation of nuclear construction in the US. The impact of news stories about the accident was no doubt a factor, but other factors were the availability of cheap natural gas, a transition away from manufacturing and toward importation of consumer products, and federal policies that tolerated air pollution in the interest of keeping coal-fired electricity cheap.

Three Mile Island reactor accident

Understanding pressurized water reactors

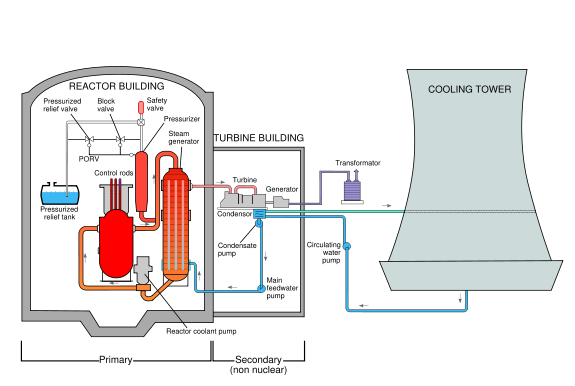

There are three major water/steam loops in most pressurized water reactors ( PWR): the primary loop, the secondary loop, and the condenser feedwater (cooling tower) loop.

The primary loop runs through the reactor. It consists of purified, demineralized water to which a small, variable amount of boron has been added for reactivity control. It is the primary thermal energy transport loop. The primary loop carries the thermal neutron fission heat energy from the fuel assemblies (the reactor's "core") to an area outside the reactor, where the energy can be more easily harnessed (via the secondary loop). This loop runs at a temperature far higher than the boiling point of water at standard atmospheric pressure, and must remain pressurized or the water will flash to steam, compromising cooling of the core. The water, which always remains in a liquid state, has two functions:

- (a) to moderate or slow neutrons so they can be more easily captured by uranium fuel

- (b) to transfer heat from the reactor.

In this reactor design, water is used as the primary loop transport medium because it is cheap, has a high thermal transport efficiency, and actually contributes to fission reaction safety. If this primary loop water is lost, neutron moderation will stop and self sustaining fission in the reactor core will be halted. (This is, of course, not desirable because under operating (or recently shutdown) conditions, decay heat alone is sufficient to melt the fuel.)

The secondary loop resembles the steam cycle in a conventional power plant. The feedwater pump moves cool water into the steam generator, a heat exchanger which uses heat from the primary loop to boil the water in the secondary loop. The resulting steam then spins a turbine that is connected to the electrical generator. Once its energy has been expended, the steam flows through a condenser, which is another type of heat exchanger that changes the steam back to feedwater and transfers the absorbed latent heat to the cooling tower water. The feedwater is then pumped back to the steam generator system and the process repeats.

The cooling tower loop provides cooling water for the condenser of the secondary loop and other plant operational cooling needs. After being heated by absorbing waste heat from the generation process, the water is cooled by flowing through the cooling tower, which in most cases is a natural draft water-to-air heat exchanger. Water lost to evaporation in the cooling tower is replenished by water from the nearby river.

Accident description

The accident occurred in the TMI-2 reactor. Although the plant had two reactors, TMI-1 was shut down for refueling at the time of the accident. The accident began when the plant's main feedwater pumps in the secondary non-nuclear cooling system failed at exactly 4:00 a.m. EST on March 28, 1979. Coincidentally, this was, to-the-minute, the first anniversary of the unit's startup. The exact cause of the failure was never determined, although it was speculated that water entered a pneumatic air line that controlled the flow through a filter known as a condensate polisher. In fact, the NRC stated that it did not need to know how the accident started since it could have been prevented at many points along the way. Because water was no longer flowing through the secondary loop, the steam generators no longer removed heat from the reactor. First the turbine, then the nuclear reactor, automatically shut down. Due to the loss of heat removal from the primary loop (the dry steam generators), the primary side pressure began to increase, which is normal and expected during shut down.

To prevent primary side pressure from becoming excessive, the pilot-operated pressurizer relief valve ( PORV), at the top of the pressurizer, opened automatically. The valve should have closed again when the excess pressure had been released, but it did not do so. The indication to the plant's operators that the signal to close the valve had been sent was, in the absence of any indication to the contrary, taken by them to mean that the valve had closed. (A "positive feedback" lamp in the control room indicating the true position of the valve was eliminated in original construction to save time, but has been retrofitted onto all similar plants after the accident.) As a result of this design error, the PORV remained open, unnoticed by the operators for several hours, and caused the pressure to continue to decrease in the system. Cooling water poured out of the stuck-open valve at the top of the pressurizer and caused the core of the reactor to overheat.

There was no dedicated instrument to measure the level of water in the core. Instead, the operators judged the level of water in the core by the level in the pressurizer (which is mounted higher than the reactor in the closed pressure loop, so intuitively, if there is water in the pressurizer then there is water in the core), and since it was high, they assumed that the core was properly covered with coolant. Due to the stuck-open PORV, the water inside the pressurizer was turbulent causing a false water level indication. Control room operators did not initially recognize the accident as a Loss of coolant accident (LOCA) since they had only ambiguous reactor water level indication and failed to properly interpret other indications of a LOCA.

Meanwhile, another problem appeared elsewhere in the plant with the emergency feedwater system, which is the backup for the main feedwater system. Following the loss of the main feed pumps, three emergency feedwater pumps started automatically, but two valves on the emergency feedwater lines were closed, preventing the feedwater from reaching the steam generators. The emergency feedwater system had been tested 42 hours prior to the accident; and, as part of the test, these valves were closed. They should have been reopened at the end of the test, but on this occasion it appeared that the valves were not reopened, through either an administrative or human error. The President's Commission requested that the FBI investigate whether these valves were closed by an act of sabotage. The valves were discovered closed about eight minutes into the accident. Once they were reopened, emergency feedwater was restored to the steam generators.

This lack of emergency feed water for eight minutes did not have a significant effect on the outcome of the accident, but did add to the confusion faced by the operators. The restoration of feedwater did not return cooling capability, however, as steam voids (areas where there is no water present) had formed in the primary loop and prevented heat transfer from the reactor to the secondary loop via the steam generator. This problem hampered efforts to cool the reactor for days.

As the pressure in the primary system continued to decrease, voids began to form in portions of the system other than the pressurizer, most notably in the reactor vessel. Because of these voids, the water in the system was redistributed and the pressurizer water level rose while overall system water inventory decreased. Thus, the pressurizer level indicator, which tells the operator the amount of coolant capable of heat removal, incorrectly indicated that system water level was rising. This caused the operators to stop adding water by turning off the emergency core cooling pumps, which had automatically started after the initial pressure decrease, due to fears the system was being overfilled. They were unaware that, because of the voids forming in the reactor vessel, the indicator could, and in this instance did, provide false readings. This erroneous indication blinded operators to the fact that water level was dropping and the reactor core was being uncovered.

With the PORV still open, the quench tank that collected the discharge from the PORV overfilled, causing the containment building sump to fill and sound an alarm at 4:11 a.m. This alarm, along with higher than normal temperatures on the PORV discharge line and unusually high containment building temperatures and pressures, were clear indications that there was an ongoing LOCA, but these indications were initially ignored by operators. At 4:15 a.m., the quench tank relief diaphragm ruptured, and radioactive coolant began to leak out into the general containment building. This radioactive coolant was pumped from the containment building sump to an auxiliary building, outside the main containment, until the sump pumps were stopped at 4:39 a.m.

After almost 80 minutes of slow temperature rise, the primary loop pumps began to cavitate as steam rather than water began to pass through them. The pumps were shut down, and it was believed that natural circulation would continue the water movement. Steam in the system locked the primary loop, and as the water stopped circulating it was converted to steam in increasing amounts. About 130 minutes after the first malfunction, the top of the reactor core was exposed and the intense heat caused a reaction to occur between the steam forming in the reactor core and the zirconium nuclear fuel rod cladding. This reaction damaged the nuclear fuel rod cladding, which released more radioactivity to the reactor coolant and produced hydrogen gas that is believed to have caused a small explosion in the containment building later that afternoon.

At 6 a.m., there was a shift change in the control room. A new arrival noticed that the temperature in the holding tanks was excessive and used a backup valve called a block valve to shut off the coolant venting, but around 950 m³ (250,000 US gallons) of coolant had already leaked from the primary loop. It was not until 165 minutes after the start of the problem that radiation alarms activated as contaminated water reached detectors — by that time, the radiation levels in the primary coolant water were around 300 times expected levels, and the plant was seriously contaminated.

At 7:00 a.m. a "Site Area Emergency" (the NRC's second highest accident level) was declared and at 7:24 a.m. the incident was upgraded to a "General Emergency" (the highest accident level) Harrisburg radio station WKBO announced a problem with the plant at 8:25 a.m. and the Associated Press announced the general emergency at 9:00 a.m.

It was still not clear to the control room staff that the primary loop water levels were low and that over half the core was exposed: a Loss of coolant accident. A group of workers took manual readings from the thermocouples and obtained a sample of primary loop water. Seven hours into the emergency, new water was pumped into the primary loop and the backup relief valve was opened to reduce pressure so that the loop could be filled with water. At nine hours, the hydrogen within the reactor building ignited and burned, but this was largely unnoticed. After 16 hours, the primary loop pumps were turned on once again, and the core temperature began to fall. A large part of the core had melted, and the system was still dangerously radioactive. Over the next week, steam and hydrogen were removed from the reactor using a recombiner and, more controversially, by venting straight to the atmosphere. It is estimated that a maximum of 13 million curies (480 petabecquerels) of radioactive noble gases were released by the event, though very little of the hazardous iodine-131 was released.

It was later found that about half the core had melted during the accident; however, the reactor vessel maintained integrity and contained the damaged fuel.

Health effects and epidemiology

The scientific community is largely agreed on the effects of the Three Mile Island accident. The consensus is that no member of the public was injured by the accident. "The average radiation dose to people living within ten miles of the plant was eight millirem, and no more than 100 millirem to any single individual. Eight millirem is about equal to a chest X-ray, and 100 millirem is about a third of the average background level of radiation received by US residents in a year.". While some studies have suggested a link between lung cancer and offsite exposures, no study has found a conclusive link between low level exposure and cancer increases. A recent study has noted that the counties surrounding TMI have the highest radon concentrations in the United States and that this may be the cause of the increased lung cancer noted in the region .

The dissenting view cites observations by locals to infer a massive radiation release from the plant. However, "to this day [late 2004], Wing's article remains the only one to present original health data supporting a link between Three Mile Island radiation exposure and cancer". This camp also notes that hundreds of out-of-court settlements have been reached with alleged victims. However, a class action lawsuit alleging that the accident caused detrimental health effects was rejected by Harrisburg U.S. District Court Judge Sylvia Rambo. The appeal of the decision in front of U.S. Third Circuit Court of Appeals also failed.

In 1979, as Pennsylvania state secretary of health in the Thornburg administration, Gordon K MacLeod MD managed the health effects of the Three Mile Island nuclear accident. He criticized Pennsylvania's preparedness, in the event of a nuclear accident, at the time for not having potassium iodide in stock, which protects the thyroid gland in the event of radiation exposure, as well as for not having any physicians on Pennsylvania's equivalent to the Nuclear Regulatory Commission.

Aftermath

U.S. President Jimmy Carter ordered a full investigation of the TMI incident. The Pennsylvania House of Representatives conducted its own investigation, which focused on the need to improve evacuation procedures. House investigators also visited the Three Mile Island site, including the control room. Many of the instruments viewed were marked with "error tags," explaining how the instrument was supposed to work and how it actually worked.

According to the IAEA, the Three Mile Island accident was a significant turning point in the global development of nuclear power PDF. From 1963 to 1979, the number of reactors under construction globally increased every year except 1971 and 1978. However, following the event, the number of reactors under construction declined every year from 1980 to 1998.

The 1979 TMI accident did not, however, initiate the demise of the U.S. nuclear power industry. As a result of post-oil-shock analysis and conclusions of overcapacity, 40 planned nuclear power plants had already been canceled between 1973 and 1979. No U.S. nuclear power plant had been authorized to begin construction since the year before TMI. Nonetheless, TMI added a significant impact on this demise: At the time of the TMI incident, 129 nuclear power plants had been approved; of those, only 53 (which were not already operating) were completed. Federal requirements became more stringent, local opposition became more strident, and construction times were significantly lengthened.

The TMI accident also had a psychological effect on the nation. Before the accident, 70 percent of the general public approved of nuclear power. After it, support for nuclear power across the country fell to about 50 percent, where it remained for decades. Recently, public support for nuclear power has been on the rise, and the George W. Bush administration has been particularly supportive of nuclear power, encouraging power companies to begin considering plans for the first new nuclear reactors in the United States in decades.

The TMI cleanup started in August 1979 and officially ended in December 1993, having cost around US$975 million. From 1985 to 1990 almost 100 tons of radioactive fuel were removed from the site. However, the contaminated cooling water that leaked into the containment building had seeped into the building's concrete, leaving the radioactive residue impossible to remove. TMI-2 had been online only three months, but now had a ruined reactor vessel and a containment building that was unsafe to walk in — it has since been permanently closed. Many similar Babcock and Wilcox reactors on order were canceled — in total, 51 American nuclear reactors were canceled from 1980 to 1984.

In the end, a few simple water level gauges on the reactor vessel might have prevented the accident. The operators' focus on a single misleading indication, the level in the pressurizer, was a significant contributing factor to the meltdown.

Unit 1, which had had its license temporarily suspended following the incident at Unit 2, was permitted to resume operations in 1985. General Public Utilities Corporation, the plant's owner, formed General Public Utilities Nuclear Corporation (GPUN) as a new subsidiary to own and operate the company's fleet of nuclear facilities, including Three Mile Island. The plant had previously been operated by Metropolitan Edison Company (Met-Ed), one of GPU's regional utility operating companies. In 1996, General Public Utilities shortened its name to GPU Inc. Three Mile Island Unit 1 was sold to AmerGen Energy Corporation, a joint venture between Philadelphia Electric Company (PECO), and British Energy, in 1998. In 2000, PECO merged with Unicom Corporation to form Exelon Corporation, which acquired British Energy's share of AmerGen in 2003. Today, AmerGen LLC is a fully owned subsidiary of Exelon Generation and owns TMI Unit 1, Oyster Creek Nuclear Generating Station, and Clinton Power Station. These three units, in addition to Exelon's other nuclear units, are operated by Exelon Nuclear Inc., an Exelon subsidiary.

Three Mile Island Unit 2 was too badly damaged and contaminated to resume operations. The reactor was gradually deactivated and mothballed in a lengthy process completed in 1993. Initially, efforts focused on the cleanup and decontamination of the site, especially the defueling of the damaged reactor. In 1988, the Nuclear Regulatory Commission announced that, although it was possible to further decontaminate the Unit 2 site, the remaining radioactivity had been sufficiently contained as to pose no threat to public health and safety. Accordingly, further cleanup efforts were deferred to allow for decay of the radiation levels and to take advantage of the potential economic benefits of retiring both Unit 1 and Unit 2 together. The defueling process was completed in 1990, and the damaged fuel was removed and disposed of in 1993. General Public Utilities was legally obliged to continue to maintain and monitor the site, and therefore retained ownership of Unit 2 when Unit 1 was sold to AmerGen in 1998. GPU Inc. was acquired by First Energy Corporation in 2001, and subsequently dissolved. First Energy then contracted out the maintenance and administration of Unit 2 to AmerGen. Unit 2 has been administered by Exelon Nuclear since 2003, when Exelon Nuclear's parent company, Exelon, bought out the remaining shares of AmerGen, inheriting First Energy's maintenance contract. Unit 2 continues to be licensed and regulated by the Nuclear Regulatory Commission in a condition known as Post Defueling Monitored Storage (PDMS).

Lessons learned

Three Mile Island has been of interest to human factors engineers as an example of how groups of people react and make decisions under stress. There is consensus that the accident was exacerbated by wrong decisions made because the operators were overwhelmed with information, much of it irrelevant, misleading or incorrect. As a result of the TMI-2 incident, nuclear reactor operator training has been improved. Before the incident it focused on diagnosing the underlying problem; afterwards, it focused on reacting to the emergency by going through a standardized checklist to ensure that the core is receiving enough coolant under sufficient pressure.

In addition to the improved operating training, improvements in quality assurance, engineering, operational surveillance and emergency planning have been instituted. Improvements in control room habitability, "sight lines" to instruments, ambiguous indications and even the placement of "trouble" tags were made; some trouble tags were covering important instrument indications during the accident. Improved surveillance of critical systems, structures and components required for cooling the plant and mitigating the escape of radionuclides during an emergency were also implemented. In addition, each nuclear site must now have an approved emergency plan to direct the evacuation of the public within a ten mile Emergency Planning Zone (EPZ) and to facilitate rapid notification and evacuation. This plan is periodically rehearsed with federal and local authorities to ensure that all groups work together quickly and efficiently.

The China Syndrome

The accident at the plant occurred 12 days after the release of the movie The China Syndrome, which featured Jane Fonda as a news anchor at a California TV station. In the film, a major nuclear plant failure almost happens while Fonda's character and her cameraman Michael Douglas are at a plant doing a series on nuclear power. She proceeds to raise awareness of how unsafe the plant was. Coincidentally, there is a scene in which Fonda's character speaks with a nuclear safety expert who says that a meltdown could render an area "the size of Pennsylvania permanently uninhabitable." Also, the fictional near-accident in the movie stems from plant operators overestimating the amount of water within the core.

After the release of the film, Fonda began lobbying against nuclear power — the only actor in the film to do so. In an attempt to counter her efforts, the nuclear physicist Edward Teller, "father of the hydrogen bomb" and long-time government science advisor, himself lobbied in favour of nuclear power, and the 71-year-old scientist eventually suffered a heart attack on May 8, 1979 which he later blamed on Fonda: "You might say that I was the only one whose health was affected by that reactor near Harrisburg. No, that would be wrong. It was not the reactor. It was Jane Fonda. Reactors are not dangerous." Rhetoric based on the movie is still used to debate for and against nuclear power.

Current Status

Today, the TMI-2 reactor is permanently shut down and defueled, with the reactor coolant system drained, the radioactive water decontaminated and evaporated, radioactive waste shipped off-site to an appropriate disposal site, reactor fuel and core debris shipped off-site to a Department of Energy facility, and the remainder of the site being monitored. The owner says it will keep the facility in long-term, monitored storage until the operating license for the TMI-1 plant expires at which time both plants will be decommissioned. TMI-1's current license expires in 2014. On January 08, 2008, AmerGen Energy Corporation, the operator of TMI-1, submitted a license renewal application to the NRC. If the license is renewed, TMI-1's license will be extended to 2034.

| Date | Event |

|---|---|

| July 1980 | Approximately 43,000 curies of krypton were vented from the reactor building. |

| July 1980 | The first manned entry into the reactor building took place. |

| Nov. 1980 | An Advisory Panel for the Decontamination of TMI-2, composed of citizens, scientists, and State and local officials, held its first meeting in Harrisburg, PA. |

| July 1984 | The reactor vessel head (top) was removed. |

| Oct. 1985 | Defueling began. |

| July 1986 | The off-site shipment of reactor core debris began. |

| Aug. 1988 | GPU submitted a request for a proposal to amend the TMI-2 license to a "possession-only" license and to allow the facility to enter long-term monitoring storage. |

| Jan. 1990 | Defueling was completed. |

| July 1990 | GPU submitted its funding plan for placing $229 million in escrow for radiological decommissioning of the plant. |

| Jan. 1991 | The evaporation of accident-generated water began. |

| April 1991 | NRC published a notice of opportunity for a hearing on GPU's request for a license amendment. |

| Feb. 1992 | NRC issued a safety evaluation report and granted the license amendment. |

| Aug. 1993 | The processing of accident-generated water was completed involving 2.23 million gallons. |

| Sept. 1993 | NRC issued a possession-only license. |

| Sept. 1993 | The Advisory Panel for Decontamination of TMI-2 held its last meeting. |

| Dec. 1993 | Post-Defueling Monitoring Storage began. |