Nitric acid

2008/9 Schools Wikipedia Selection. Related subjects: Chemical compounds

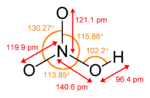

| Nitric acid | |

|---|---|

|

|

| IUPAC name | Nitric acid |

| Other names | Aqua fortis; Spirit of nitre; Salpetre acid |

| Identifiers | |

| CAS number | [7697-37-2] |

| RTECS number | QU5775000 |

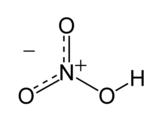

| SMILES | O[N+](=O)[O-] |

| Properties | |

| Molecular formula | HNO3 |

| Molar mass | 63.012 g/mol |

| Appearance | Clear, colorless liquid |

| Density | 1.51 g/cm³, colorless liquid |

| Melting point |

-42 °C (231 K) |

| Boiling point |

83 °C (356 K) |

| Solubility in water | miscible |

| Viscosity | ? cP at ? °C |

| Dipole moment | 2.17 ± 0.02 D |

| Hazards | |

| EU classification | Oxidant (O) Corrosive (C) |

| R-phrases | R8, R35 |

| S-phrases | (S1/2), S23, S26, S36, S45 |

| Flash point | not applicable |

| Related compounds | |

| Related compounds | Nitrous acid Dinitrogen pentoxide |

| Except where noted otherwise, data are given for materials in their standard state (at 25 °C, 100 kPa) Infobox disclaimer and references |

|

Nitric acid (HNO3), also known as aqua fortis and spirit of nitre, is a highly corrosive and toxic strong acid that can cause severe burns. The synthesis of nitric acid was first recorded circa 800 AD by the Muslim alchemist Jabir ibn Hayyan.

Colorless when pure, older samples tend to acquire a yellow cast due to the accumulation of oxides of nitrogen. If the solution contains more than 86% nitric acid, it is referred to as fuming nitric acid. Fuming nitric acid is characterized as white fuming nitric acid and red fuming nitric acid, depending on the amount of nitrogen dioxide present.

Properties

Pure anhydrous nitric acid (100%) is a colorless liquid with a density of 1522 kg/m³ which solidifies at -42 °C to form white crystals and boils at 83 °C. When boiling in light, even at room temperature, there is a partial decomposition with the formation of nitrogen dioxide following the reaction:

- 4HNO3 → 2H2O + 4NO2 + O2 (72°C)

which means that anhydrous nitric acid should be stored below 0 °C to avoid decomposition. The nitrogen dioxide (NO2) remains dissolved in the nitric acid coloring it yellow, or red at higher temperatures. While the pure acid tends to give off white fumes when exposed to air, acid with dissolved nitrogen dioxide gives off reddish-brown vapours, leading to the common name "red fuming acid" or "fuming nitric acid".

Nitric acid is miscible with water in all proportions and distillation gives an azeotrope with a concentration of 68% HNO3 and a boiling temperature of 120.5 °C at 1 atm. Two solid hydrates are known; the monohydrate (HNO3·H2O) and the trihydrate (HNO3·3H2O).

Nitrogen oxides (NOx) are soluble in nitric acid and this property influences more or less, all the physical characteristics depending on the concentration of the oxides. These mainly include the vapor pressure above the liquid and the boiling temperature, as well as the colour mentioned above.

Nitric acid is subject to thermal or light decomposition with increasing concentration and this may give rise to some non-negligible variations in the vapour pressure above the liquid because the nitrogen oxides produced dissolve partly or completely in the acid.

Acidic properties

Being a typical acid, nitric acid reacts with alkalis, basic oxides, and carbonates to form salts, such as ammonium nitrate. Due to its oxidizing nature, nitric acid generally does not liberate hydrogen on reaction with metals and the resulting salts are usually in the higher oxidized states. For this reason, heavy corrosion can be expected and should be guarded against by the appropriate use of corrosion resistant metals or alloys.

Nitric acid has an acid dissociation constant (pKa) of −1.4: in aqueous solution, it almost completely (93% at 0.1 mol/L) ionizes into the nitrate ion NO3− and a hydrated proton, known as a hydronium ion, H3O+.

- HNO3 + H2O → H3O+ + NO3-

Oxidizing properties

Reactions with metals

Being a powerful oxidizing agent, nitric acid reacts violently with many organic materials and the reactions may be explosive. Depending on the acid concentration, temperature and the reducing agent involved, the end products can be variable. Reaction then takes place with all metals except the precious metal series and certain alloys. As a general rule of course, oxidizing reactions occur primarily with the concentrated acid, favouring the formation of nitrogen dioxide (NO2).

- Cu + 4HNO3 → Cu(NO3)2 + 2NO2 + 2H2O

The acidic properties tend to dominate with dilute acid, coupled with the preferential formation of nitrogen oxide (NO).

- 3Cu + 8HNO3 → 3Cu(NO3)2 + 2NO + 4H2O

Since nitric acid is an oxidizing agent, hydrogen (H2) is rarely formed. Only magnesium (Mg) and calcium (Ca) react with cold, dilute nitric acid to give hydrogen:

- Mg(s) + 2HNO3 (aq) → Mg(NO3)2 (aq) + H2 (g)

Passivation

Although chromium (Cr), iron (Fe) and aluminium (Al) readily dissolve in dilute nitric acid, the concentrated acid forms a metal oxide layer that protects the metal from further oxidation, which is called passivation.

Reactions with non-metals

Reaction with non-metallic elements, with the exception of silicon and halogens, usually oxidizes them to their highest oxidation states as acids with the formation of nitrogen dioxide for concentrated acid and nitrogen oxide for dilute acid.

- C + 4HNO3 → CO2 + 4NO2 + 2H2O

or

- 3C + 4HNO3 → 3CO2 + 4NO + 2H2O

Grades

White fuming nitric acid, also called 100% nitric acid or WFNA, is very close to the anhydrous nitric acid product. One specification for white fuming nitric acid is that it has a maximum of 2% water and a maximum of 0.5% dissolved NO2.

Red fuming nitric acid, or RFNA, contains substantial quantities of dissolved nitrogen dioxide (NO2) leaving the solution with a reddish-brown colour. One formulation of RFNA specifies a minimum of 17% NO2, another specifies 13% NO2.

An inhibited fuming nitric acid (either IWFNA, or IRFNA) can be made by the addition of 0.6 to 0.7% hydrogen fluoride, HF. This fluoride is added for corrosion resistance in metal tanks (the fluoride creates a metal fluoride layer that protects the metal).

Industrial production

Nitric acid is made by mixing nitrogen dioxide (NO2) with water in the presence of oxygen or air to oxidize the nitrous acid also produced by the reaction.

Dilute nitric acid may be concentrated by distillation up to 68% acid, which is an azeotropic mixture with 32% water. Further concentration involves distillation with sulfuric acid which acts as a dehydrating agent. In the laboratory, such distillations must be done with all-glass apparatus at reduced pressure, to prevent decomposition of the acid.

Commercial grade nitric acid solutions are usually between 52% and 68% nitric acid. Commercial production of nitric acid is via the Ostwald process, named after Wilhelm Ostwald.

The acid can also be synthesized by oxidizing ammonia, but the product is diluted by the water also formed as part of the reaction. However, this method is important in producing ammonium nitrate from ammonia derived from the Haber process, because the final product can be produced from nitrogen, hydrogen, and oxygen as the sole feedstocks.

Laboratory synthesis

In laboratory, nitric acid can be made from copper(II) nitrate or by reacting approximately equal masses of potassium nitrate (KNO3) with 96% sulfuric acid (H2SO4), and distilling this mixture at nitric acid's boiling point of 83 °C until only a white crystalline mass, potassium hydrogen sulfate (KHSO4), remains in the reaction vessel. The obtained red fuming nitric acid may be converted to the white nitric acid.

- H2SO4 + KNO3 → KHSO4 + HNO3

The dissolved NOx are readily removed using reduced pressure at room temperature (10-30 min at 200 mmHg or 27 kPa) to give white fuming nitric acid. This procedure can also be performed under reduced pressure and temperature in one step in order to produce less nitrogen dioxide gas.

Uses

IWFNA may be used as the oxidizer in liquid fuel rockets. IRFNA was one of 3 liquid fuel components for the BOMARC missile

A solution of nitric acid and alcohol, Nital, is used for etching of metals to reveal the microstructure.

Commercially available aqueous blends of 5-30% nitric acid and 15-40% phosphoric acid are commonly used for cleaning food and dairy equipment primarily to remove precipitated calcium and magnesium compounds (either deposited from the process stream or resulting from the use of hard water during production and cleaning).

Nitration

Nitric acid is used in the manufacture of nitrate-containing explosives such as nitroglycerin, trinitrotoluene (TNT) and cyclotrimethylenetrinitramine (RDX), as well as fertilizers such as ammonium nitrate.

Digestion

In elemental analysis by ICP-MS and ICP-AES, dilute nitric acid (0.5 to 2.0 %) is used as a matrix compound for determining metal traces in solutions. Ultrapure acid is required for such determination, because small amounts of metal ions could affect the result of the analysis.

Woodworking

In a low concentration (approximately 10%), nitric acid is often used to artificially age pine and maple. The colour produced is a grey-gold very much like very old wax or oil finished wood ( wood finishing).

Other uses

Alone, it is useful in metallurgy and refining as it reacts with most metals, and in organic syntheses. When mixed with hydrochloric acid, nitric acid forms aqua regia, one of the few reagents capable of dissolving gold and platinum.

Safety

Nitric acid is a powerful oxidizing agent, and the reactions of nitric acid with compounds such as cyanides, carbides, and metallic powders can be explosive. Reactions of nitric acid with many organic compounds, such as turpentine, are violent and hypergolic (i.e., self-igniting).

Concentrated nitric acid dyes human skin yellow due to a reaction with the keratin. These yellow stains turn orange when neutralized.