Glass

2008/9 Schools Wikipedia Selection. Related subjects: Materials science

Glass in the common sense refers to a hard, brittle, transparent, solid, such as that used for windows, many bottles, or eyewear, including, but not limited to, soda-lime glass, borosilicate glass, acrylic glass, sugar glass, isinglass (Muscovy-glass), or aluminium oxynitride.

In the technical sense, glass is an inorganic product of fusion which has been cooled to a rigid condition without crystallizing. Many glasses contain silica as their main component and glass former.

In the scientific sense the term glass is often extended to all amorphous solids (and melts that easily form amorphous solids), including plastics, resins, or other silica-free amorphous solids. In addition, besides traditional melting techniques, any other means of preparation are considered, such as ion implantation, and the sol-gel method. However, glass science commonly includes only inorganic amorphous solids, while plastics and similar organics are covered by polymer science, biology and further scientific disciplines.

The optical and physical properties of glass make it suitable for applications such as flat glass, container glass, optics and optoelectronics material, laboratory equipment, thermal insulator ( glass wool), reinforcement fibre ( glass-reinforced plastic, glass fibre reinforced concrete), and art.

General properties, uses, occurrence

Ordinary glass is prevalent due to its transparency to visible light. This transparency is due to an absence of electronic transition states in the range of visible light. The homogeneity of the glass on length scales greater than the wavelength of visible light also contributes to its transparency as heterogeneities would cause light to be scattered, breaking up any coherent image transmission. Many household objects are made of glass. Drinking glasses, bowls and bottles are often made of glass, as are light bulbs, mirrors, aquaria, cathode ray tubes, computer flat panel displays, and windows.

In research laboratories, flasks, test tubes, and other laboratory equipment are often made of borosilicate glass for its low coefficient of thermal expansion, giving greater resistance to thermal shock and greater accuracy in measurements. For high-temperature applications, quartz glass is used, although it is very difficult to work. Most laboratory glassware is mass-produced, but large laboratories also keep a glassblower on staff for preparing custom made glass equipment.

Sometimes, glass is created naturally from volcanic lava, lightning strikes, or meteorite impacts (e.g., Lechatelierite, Fulgurite, Darwin Glass, Volcanic Glass, Tektites). If the lava is felsic this glass is called obsidian, and is usually black with impurities. Obsidian is a raw material for flintknappers, who have used it to make extremely sharp glass knives since the stone age.

Glass sometimes occurs in nature resulting from human activity, for example trinitite (from nuclear testing) and beach glass.

Glass in buildings

Glass is commonly used in buildings as transparent windows, internal glazed partitions, and as architectural features. It is also possible to use glass as a structural material, for example, in beams and columns, as well as in the form of "fins" for wind reinforcement, which are visible in many glass frontages like large shop windows. Safe load capacity is, however, limited; although glass has a high theoretical yield stress, it is very susceptible to brittle (sudden) failure, and has a tendency to shatter upon localized impact. This particularly limits its use in columns, as there is a risk of vehicles or other heavy objects colliding with and shattering the structural element. One well-known example of a structure made entirely from glass is the northern entrance to Buchanan Street subway station in Glasgow.

Glass in buildings can be of a safety type, including wired, heat strengthened (tempered) and laminated glass. Glass fibre insulation is common in roofs and walls. Foamed glass, made from waste glass, can be used as lightweight, closed-cell insulation. As insulation, glass (e.g., fibreglass) is also used. In the form of long, fluffy-looking sheets, it is commonly found in homes. Fibreglass insulation is used particularly in attics, and is given an R-rating, denoting the insulating ability.

Technological applications

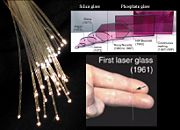

Pure SiO2 glass (the same chemical compound as quartz, or, in its polycrystalline form, sand) does not absorb UV light and is used for applications that require transparency in this region. Large natural single crystals of quartz are pure silicon dioxide, and upon crushing are used for high quality specialty glasses. Synthetic amorphous silica, an almost 100 % pure form of quartz, is the raw material for the most expensive specialty glasses, such as optical fibre core. Undersea cables have sections doped with erbium, which amplify transmitted signals by laser emission from within the glass itself. Amorphous SiO2 is also used as a dielectric material in integrated circuits due to the smooth and electrically neutral interface it forms with silicon.

Optical instruments such as glasses, cameras, microscopes, telescopes, and planetaria are based on glass lenses, mirrors, and prisms. The glasses used for making these instruments are categorized using a six-digit glass code, or alternatively a letter-number code from the Schott Glass catalogue. For example, BK7 is a low- dispersion borosilicate crown glass, and SF10 is a high-dispersion dense flint glass. The glasses are arranged by composition, refractive index, and Abbe number.

Glass polymerization is a technique that can be used to incorporate additives that modify the properties of glass that would otherwise be destroyed during high temperature preparation. Sol gel is an example of glass polymerization and enables embedding of organic and bioactive molecules, to add a new level of functionality to glass.

Glass production

Glass production history

Glass melting technology has passed through several stages:

- Glass was manufactured in open pits, ca. 3000 B.C. until the invention of the blowpipe in ca. 250 B.C.

- The mobile wood-fired melting pot furnace was used until around the 17th century by traveling glass manufacturers.

- Around 1688, a process for casting glass was developed, which led to glass becoming a much more commonly used material.

- The local pot furnace, fired by wood and coal was used between 1600 and 1850.

- The cylinder method of creating flat glass was used in the United States of America for the first time in the 1820s. It was used to commercially produce windows.

- The invention of the glass pressing machine in 1827 allowed the mass production of inexpensive glass products.

- The gas-heated melting pot and tank furnaces dating from 1860, followed by the electric furnace of 1910.

- Hand-blown sheet glass was replaced in the 20th century by rolled plate glass.

- The float glass process was invented in the 1950s.

Glass ingredients

Pure silica (SiO2) has a "glass melting point"— at a viscosity of 10 Pa·s (100 P)— of over 2300 °C (4200 °F). While pure silica can be made into glass for special applications (see fused quartz), other substances are added to common glass to simplify processing. One is sodium carbonate (Na2CO3), which lowers the melting point to about 1500 °C (2700 °F) in soda-lime glass; " soda" refers to the original source of sodium carbonate in the soda ash obtained from certain plants. However, the soda makes the glass water soluble, which is usually undesirable, so lime ( calcium oxide (CaO), generally obtained from limestone), some magnesium oxide (MgO) and aluminium oxide are added to provide for a better chemical durability. The resulting glass contains about 70 to 74 percent silica by weight and is called a soda-lime glass. Soda-lime glasses account for about 90 percent of manufactured glass.

As well as soda and lime, most common glass has other ingredients added to change its properties. Lead glass, such as lead crystal or flint glass, is more 'brilliant' because the increased refractive index causes noticeably more "sparkles", while boron may be added to change the thermal and electrical properties, as in Pyrex. Adding barium also increases the refractive index. Thorium oxide gives glass a high refractive index and low dispersion, and was formerly used in producing high-quality lenses, but due to its radioactivity has been replaced by lanthanum oxide in modern glasses. Large amounts of iron are used in glass that absorbs infrared energy, such as heat absorbing filters for movie projectors, while cerium(IV) oxide can be used for glass that absorbs UV wavelengths (biologically damaging ionizing radiation).

Besides the chemicals mentioned, in some furnaces recycled glass ("cullet") is added, originating from the same factory or other sources. Cullet leads to savings not only in the raw materials, but also in the energy consumption of the glass furnace. However, impurities in the cullet may lead to product and equipment failure. Fining agents such as sodium sulfate, sodium chloride, or antimony oxide are added to reduce the bubble content in the glass.

A further raw material used in the production of soda-lime and fibre glass is calumite, which is a glassy granular by-product of the iron making industry, containing mainly silica, calcium oxide, alumina, magnesium oxide (and traces of iron oxide).

For obtaining the desired glass composition, the correct raw material mixture (batch) must be determined by glass batch calculation.

Contemporary glass production

Following the glass batch preparation and mixing the raw materials are transported to the furnace. Soda-lime glass for mass production is melted in gas fired units. Smaller scale furnaces for specialty glasses include electric melters, pot furnaces and day tanks.

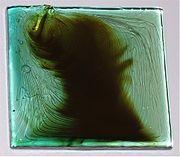

After melting, homogenization and refining (removal of bubbles) the glass is formed. Flat glass for windows and similar applications is formed by the float glass process, developed between 1953 and 1957 by Sir Alastair Pilkington and Kenneth Bickerstaff of the UK's Pilkington Brothers, which created a continuous ribbon of glass using a molten tin bath on which the molten glass flows unhindered under the influence of gravity. The top surface of the glass is subjected to nitrogen under pressure to obtain a polished finish. Container glass for common bottles and jars is formed by blowing and pressing methods. Further glass forming techniques are summarized in the table Glass forming techniques.

Once the desired form is obtained, glass is usually annealed for the removal of stresses.

Various surface treatment techniques, coatings, or lamination may follow to improve the chemical durability ( glass container coatings, glass container internal treatment), strength ( toughened glass, bulletproof glass, windshields), or optical properties ( insulated glazing, anti-reflective coating).

Glassmaking in the laboratory

New chemical glass compositions or new treatment techniques can be initially investigated in small-scale laboratory experiments. The raw materials for laboratory-scale glass melts are often different from those used in mass production because the cost factor has a low priority. In the laboratory mostly pure chemicals are used. Care must be taken that the raw materials have not reacted with moisture or other chemicals in the environment (such as alkali oxides and hydroxides, alkaline earth oxides and hydroxides, or boron oxide), or that the impurities are quantified (loss on ignition). Evaporation losses during glass melting should be considered during the selection of the raw materials, e.g., sodium selenite may be preferred over easily evaporating SeO2. Also, more readily reacting raw materials may be preferred over relatively inert ones, such as Al(OH)3 over Al2O3. Usually, the melts are carried out in platinum crucibles to reduce contamination from the crucible material. Glass homogeneity is achieved by homogenizing the raw materials mixture ( glass batch), by stirring the melt, and by crushing and re-melting the first melt. The obtained glass is usually annealed to prevent breakage during processing.

See also: Optical lens design, Fabrication and testing of optical components

Silica-free glasses

Besides common silica-based glasses, many other inorganic and organic materials may also form glasses, including plastics (e.g., acrylic glass), carbon, metals, carbon dioxide (see below), phosphates, borates, chalcogenides, fluorides, germanates (glasses based on GeO2), tellurites (glasses based on TeO2), antimonates (glasses based on Sb2O3), arsenates (glasses based on As2O3), titanates (glasses based on TiO2), tantalates (glasses based on Ta2O5), nitrates, carbonates and many other substances.

Some glasses that do not include silica as a major constituent may have physico-chemical properties useful for their application in fibre optics and other specialized technical applications. These include fluorozirconate, fluoroaluminate, aluminosilicate, phosphate and chalcogenide glasses.

Under extremes of pressure and temperature solids may exhibit large structural and physical changes which can lead to polyamorphic phase transitions. In 2006 Italian scientists created an amorphous phase of carbon dioxide using extreme pressure. The substance was named amorphous carbonia(a-CO2) and exhibits an atomic structure resembling that of Silica.

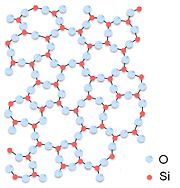

The physics of glass

The standard definition of a glass (or vitreous solid) requires the solid phase to be formed by rapid melt quenching. Glass is therefore formed via a supercooled liquid and cooled sufficiently rapidly (relative to the characteristic crystallisation time) from its molten state through its glass transition temperature, Tg, that the supercooled disordered atomic configuration at Tg, is frozen into the solid state. Generally, the structure of a glass exists in a metastable state with respect to its crystalline form, although in certain circumstances, for example in atactic polymers, there is no crystalline analogue of the amorphous phase . By definition as an amorphous solid, the atomic structure of a glass lacks any long range translational periodicity. However, by virtue of the local chemical bonding constraints glasses do possess a high degree of short-range order with respect to local atomic polyhedra. It is deemed that the bonding structure of glasses, although disordered, has the same symmetry signature ( Hausdorff-Besicovitch dimensionality) as for crystalline materials.

Glass versus a supercooled liquid

Glass is generally treated as an amorphous solid rather than a liquid, though both views can be justified. However, the notion that glass flows to an appreciable extent over extended periods of time is not supported by empirical research or theoretical analysis (see viscosity of amorphous materials). From a more commonsense point of view, glass should be considered a solid since it is rigid according to everyday experience.

Some people consider glass to be a liquid due to its lack of a first-order phase transition where certain thermodynamic variables such as volume, entropy and enthalpy are continuous through the glass transition temperature. However, the glass transition temperature may be described as analogous to a second-order phase transition where the intensive thermodynamic variables such as the thermal expansivity and heat capacity are discontinuous. Despite this, thermodynamic phase transition theory does not entirely hold for glass, and hence the glass transition cannot be classed as a genuine thermodynamic phase transition.

Although the atomic structure of glass shares characteristics of the structure in a supercooled liquid, glass is generally classed as solid below its glass transition temperature. There is also the problem that a supercooled liquid is still a liquid and not a solid but it is below the freezing point of the material and will crystallize almost instantly if a crystal is added as a core. The change in heat capacity at a glass transition and a melting transition of comparable materials are typically of the same order of magnitude indicating that the change in active degrees of freedom is comparable as well. Both in a glass and in a crystal it is mostly only the vibrational degrees of freedom that remain active, whereas rotational and translational motion becomes impossible explaining why glasses and crystalline materials are hard.

Behaviour of antique glass

The observation that old windows are often thicker at the bottom than at the top is often offered as supporting evidence for the view that glass flows over a matter of centuries. It is then assumed that the glass was once uniform, but has flowed to its new shape, which is a property of liquid. The likely source of this unfounded belief is that when panes of glass were commonly made by glassblowers, the technique used was to spin molten glass so as to create a round, mostly flat and even plate (the Crown glass process, described above). This plate was then cut to fit a window. The pieces were not, however, absolutely flat; the edges of the disk would be thicker because of centripetal force relaxation. When actually installed in a window frame, the glass would be placed thicker side down for the sake of stability and visual sparkle. Occasionally such glass has been found thinner side down or on either side of the window's edge, as would be caused by carelessness at the time of installation.

Mass production of glass window panes in the early twentieth century caused a similar effect. In glass factories, molten glass was poured onto a large cooling table and allowed to spread. The resulting glass is thicker at the location of the pour, located at the centre of the large sheet. These sheets were cut into smaller window panes with nonuniform thickness. Modern glass intended for windows is produced as float glass and is very uniform in thickness.

Several other points exemplify the misconception of the 'cathedral glass' theory:

- Writing in the American Journal of Physics, physicist Edgar D. Zanotto states "...the predicted relaxation time for GeO2 at room temperature is 1032 years. Hence, the relaxation period (characteristic flow time) of cathedral glasses would be even longer".

- If medieval glass has flowed perceptibly, then ancient Roman and Egyptian objects should have flowed proportionately more — but this is not observed. Similarly, prehistoric obsidian blades should have lost their edge; this is not observed either (although obsidian may have a different viscosity from window glass).

- If glass flows at a rate that allows changes to be seen with the naked eye after centuries, then the effect should be noticeable in antique telescopes. Any slight deformation in the antique telescopic lenses would lead to a dramatic decrease in optical performance, a phenomenon that is not observed.

- There are many examples of centuries-old glass shelving which has not bent, even though it is under much higher stress from gravitational loads than vertical window glass.

Some glasses have a glass transition temperature close to or below room temperature. The behaviour of a material that has a glass transition close to room temperature depends upon the timescale during which the material is manipulated. If the material is hit it may break like a solid glass, however if the material is left on a table for a week it may flow like a liquid. This simply means that for the fast timescale its transition temperature is above room temperature, but for the slow one it is below. The shift in temperature with timescale is not very large however as indicated by the transition of polypropylene glycol of -72 °C and -71 °C over different timescales. To observe window glass flowing as liquid at room temperature we would have to wait a much longer time than any human can exist. Therefore it is safe to consider a glass a solid far enough below its transition temperature: Cathedral glass does not flow because its glass transition temperature is many hundreds of degrees above room temperature. Close to this temperature there are interesting time-dependent properties. One of these is known as aging. Many polymers that we use in daily life such as rubber, polystyrene and polypropylene are in a glassy state but they are not too far below their glass transition temperature. Their mechanical properties may well change over time and this is serious concern when applying these materials in construction.

Physical properties

The following table lists some physical properties of common glasses. Unless otherwise stated, the technical glass compositions and many experimentally determined properties are taken from one large study. Unless stated otherwise, the properties of fused silica (quartz glass) and germania glass are derived from the SciGlass glass database by forming the arithmetic mean of all the experimental values from different authors (in general more than 10 independent sources for quartz glass and Tg of germanium oxide glass). Those values marked in italic font have been interpolated from similar glass compositions (see Calculation of glass properties) due to the lack of experimental data.

| Properties | Soda-lime glass (for containers) | Borosilicate (low expansion, similar to Pyrex, Duran) | Glass wool (for thermal insulation) | Special optical glass (similar to Lead crystal) |

Fused silica | Germania glass | Germanium selenide glass |

|---|---|---|---|---|---|---|---|

| Chemical composition, wt% |

74 SiO2, 13 Na2O, 10.5 CaO, 1.3 Al2O3, 0.3 K2O, 0.2 SO3, 0.2 MgO, 0.01 TiO2, 0.04 Fe2O3 | 81 SiO2, 12.5 B2O3, 4 Na2O, 2.2 Al2O3, 0.02 CaO, 0.06 K2O | 63 SiO2, 16 Na2O, 8 CaO, 3.3 B2O3, 5 Al2O3, 3.5 MgO, 0.8 K2O, 0.3 Fe2O3, 0.2 SO3 | 41.2 SiO2, 34.1 PbO, 12.4 BaO, 6.3 ZnO, 3.0 K2O, 2.5 CaO, 0.35 Sb2O3, 0.2 As2O3 | SiO2 | GeO2 | GeSe2 |

| Viscosity log(η, Pa·s) = A + B / (T in °C - To) |

550-1450°C: A = -2.309 B = 3922 To = 291 |

550-1450°C: A = -2.834 B = 6668 To = 108 |

550-1400°C: A = -2.323 B = 3232 To = 318 |

500-690°C: A = -35.59 B = 60930 To = -741 |

1140-2320°C: A = -7.766 B = 27913 To = -271.7 |

515-1540°C: A = -11.044 B = 30979 To = -837 |

|

| Glass transition temperature, Tg, °C |

573 | 536 | 551 | ~540 | 1140 | 526 ± 27 | 395 |

| Coefficient of thermal expansion, ppm/K, ~100-300°C |

9 | 3.5 | 10 | 7 | 0.55 | 7.3 | |

| Density at 20°C, g/cm3 |

2.52 | 2.235 | 2.550 | 3.86 | 2.203 | 3.65 | 4.16 |

| Refractive index nD at 20°C | 1.518 | 1.473 | 1.531 | 1.650 | 1.459 | 1.608 | 1.7 |

| Dispersion at 20°C, 104×(nF-nC) |

86.7 | 72.3 | 89.5 | 169 | 67.8 | 146 | |

| Young's modulus at 20°C, GPa |

72 | 65 | 75 | 67 | 72 | 43.3 | |

| Shear modulus at 20°C, GPa |

29.8 | 28.2 | 26.8 | 31.3 | |||

| Liquidus temperature, °C |

1040 | 1070 | 1715 | 1115 | |||

| Heat capacity at 20°C, J/(mol·K) |

49 | 50 | 50 | 51 | 44 | 52 | |

| Surface tension, at ~1300°C, mJ/m2 |

315 | 370 | 290 | ||||

| Chemical durability, Hydrolytic class, after ISO 719 |

3 | 1 | 3 |

Colour

Colors in glass may be obtained by addition of coloring ions that are homogeneously distributed and by precipitation of finely dispersed particles (such as in photochromic glasses). Ordinary soda-lime glass appears colorless to the naked eye when it is thin, although iron(II) oxide (FeO) impurities of up to 0.1 wt% produce a green tint which can be viewed in thick pieces or with the aid of scientific instruments. Further FeO and Cr2O3 additions may be used for the production of green bottles. Sulfur, together with carbon and iron salts, is used to form iron polysulfides and produce amber glass ranging from yellowish to almost black. Manganese dioxide can be added in small amounts to remove the green tint given by iron(II) oxide.

History

Naturally occurring glass, especially obsidian, has been used by many Stone Age societies across the globe for the production of sharp cutting tools and, due to its limited source areas, was extensively traded. According to Pliny the Elder, Phoenician traders were the first to stumble upon glass manufacturing techniques at the site of the Belus River. Agricola, De re metallica, reported a traditional serendipitous "discovery" tale of familiar type:

"The tradition is that a merchant ship laden with nitrum being moored at this place, the merchants were preparing their meal on the beach, and not having stones to prop up their pots, they used lumps of nitrum from the ship, which fused and mixed with the sands of the shore, and there flowed streams of a new translucent liquid, and thus was the origin of glass."

This account is more a reflection of Roman experience of glass production, however, as white silica sand from this area was used in the production of Roman glass due to its low impurity levels. But in general archaeological evidence suggests that the first true glass was made in coastal north Syria, Mesopotamia or Old Kingdom Egypt. Due to Egypt's favourable environment for preservation, the majority of well-studied early glass is found in Egypt, although some of this is likely to have been imported. The earliest known glass objects, of the mid third millennium BC, were beads, perhaps initially created as accidental by-products of metal-working slags or during the production of faience, a pre-glass vitreous material made by a process similar to glazing.

During the Late Bronze Age in Egypt and Western Asia there was an explosion in glass-making technology. Archaeological finds from this period include coloured glass ingots, vessels (often coloured and shaped in imitation of highly prized wares of semi-precious stones) and the ubiquitous beads. The alkali of Syrian and Egyptian glass was soda ash, sodium carbonate, which can be extracted from the ashes of many plants, notably halophile seashore plants: (see saltwort). The earliest vessels were 'core-wound', produced by winding a ductile rope of metal round a shaped core of sand and clay over a metal rod, then fusing it with repeated reheatings. Threads of thin glass of different colours made with admixtures of oxides were subsequently wound around these to create patterns, which could be drawn into festoons with a metal raking tools. The vessel would then be rolled flat ('marvered') on a slab in order to press the decorative threads into its body. Handles and feet were applied separately. The rod was subsequently allowed to cool as the glass slowly annealed and was eventually removed from the centre of the vessel, after which the core material was scraped out. Glass shapes for inlays were also often created in moulds. Much early glass production, however, relied on grinding techniques borrowed from stone working. This meant that the glass was ground and carved in a cold state.

By the 15th century BC extensive glass production was occurring in Western Asia and Egypt. It is thought the techniques and recipes required for the initial fusing of glass from raw materials was a closely guarded technological secret reserved for the large palace industries of powerful states. Glass workers in other areas therefore relied on imports of pre-formed glass, often in the form of cast ingots such as those found on the Ulu Burun shipwreck off the coast of Turkey.

Glass remained a luxury material, and the disasters that overtook Late Bronze Age civilisations seem to have brought glass-making to a halt. It picked up again in its former sites, in Syria and Cyprus, in the ninth century BC, when the techniques for making colourless glass were discovered. In Egypt glass-making did not revive until it was reintroduced in Ptolemaic Alexandria. Core-formed vessels and beads were still widely produced, but other techniques came to the fore with experimentation and technological advancements. During the Hellenistic period many new techniques of glass production were introduced and glass began to be used to make larger pieces, notably table wares. Techniques developed during this period include 'slumping' viscous (but not fully molten) glass over a mould in order to form a dish and ' millefiori' (meaning 'thousand flowers') technique, where canes of multi-coloured glass were sliced and the slices arranged together and fused in a mould to create a mosaic-like effect. It was also during this period that colourless or decoloured glass began to be prized and methods for achieving this effect were investigated more fully.

During the first century BC glass blowing was discovered on the Syro-Palestinian coast, revolutionising the industry and laying the way for the explosion of glass production that occurred throughout the Roman world. Over the next 1000 years glass making and working continued and spread through southern Europe and beyond.

South Asia

Indigenous development of glass technology in South Asia may have begun in 1730 BCE. Evidence of this culture includes a red-brown glass bead along with a hoard of beads dating to 1730 BCE, making it the earliest attested glass from the Indus Valley locations. Glass discovered from later sites dating from 600-300 BCE displays common colour.

Chalcolithic evidence of glass has been found in Hastinapur, India. Some of the texts which mention glass in India are the Shatapatha Brahmana and Vinaya Pitaka. However, the first unmistakable evidence in large quantities, dating from the 3rd century BCE, has been uncovered from the archaeological site in Taxila, Pakistan.

By the beginning of the Common Era, glass was being used for ornaments and casing in South Asia. Contact with the Greco-Roman world added newer techniques, and Indians artisans mastered several techniques of glass molding, decorating and coloring by the early centuries of the Common Era. Satavahana period of India further reveals short cylinders of composite glass, including those displaying a lemon yellow matrix covered with green glass.

Romans

A full discussion of Roman glass making and working can be found on the Roman glass page.

Anglo-Saxon world

Evidence for glass making, working and use in the 5th to 8th centuries in England is discussed in the Anglo-Saxon glass page.

Islamic world

In the medieval Islamic world, the first clear, colourless, high-purity glasses were produced by Muslim chemists, architects and engineers in the 9th century. Examples include Silica glass and colourless high-purity glass invented by Abbas Ibn Firnas (810-887), who was the first to produce glass from sand and stones. The Arab poet al- Buhturi (820-897) described the clarity of such glass, "Its colour hides the glass as if it is standing in it without a container."

Stained glass was also first produced by Muslim architects in Southwest Asia using coloured glass rather than stone. In the 8th century, the Arab chemist Jabir ibn Hayyan (Geber) scientifically described 46 original recipes for producing coloured glass in Kitab al-Durra al-Maknuna (The Book of the Hidden Pearl), in addition to 12 recipes inserted by al-Marrakishi in a later edition of the book.

The parabolic mirror was first described by Ibn Sahl in his On the Burning Instruments in the 10th century, and later described again in Ibn al-Haytham's On Burning Mirrors and Book of Optics (1021). By the 11th century, clear glass mirrors were being produced in Islamic Spain. The first glass factories were also built by Muslim craftsmen in the Islamic world. The first glass factories in Christian Europe were later built in the 11th century by Muslim Egyptian craftsmen in Corinth, Greece.

Medieval Europe

Glass objects from the 7th and 8th centuries have been found on the island of Torcello near Venice. These form an important link between Roman times and the later importance of that city in the production of the material. Around 1000 AD, an important technical breakthrough was made in Northern Europe when soda glass, produced from white pebbles and burnt vegetation was replaced by glass made from a much more readily available material: potash obtained from wood ashes. From this point on, northern glass differed significantly from that made in the Mediterranean area, where soda remained in common use.

Until the 12th century, stained glass -- glass to which metallic or other impurities had been added for coloring -- was not widely used.

The 11th century saw the emergence in Germany of new ways of making sheet glass by blowing spheres. The spheres were swung out to form cylinders and then cut while still hot, after which the sheets were flattened. This technique was perfected in 13th century Venice.

The Crown glass process was used up to the mid-19th century. In this process, the glassblower would spin approximately 9 pounds (4 kg) of molten glass at the end of a rod until it flattened into a disk approximately 5 feet (1.5 m) in diameter. The disk would then be cut into panes.

Late medieval Northern Europe

Glass making in late medieval Northern Europe is discussed in the article on Forest glass.

Murano glassmaking

The centre for glassmaking from the 14th century was the island of Murano, which developed many new techniques and became the centre of a lucrative export trade in dinnerware, mirrors, and other luxury items. What made Venetian Murano glass significantly different was that the local quartz pebbles were almost pure silica, and were ground into a fine clear sand that was combined with soda ash obtained from the Levant, for which the Venetians held the sole monopoly. The clearest and finest glass is tinted in two ways: firstly, a small or large amount of a natural coloring agent is ground and melted with the glass. Many of these coloring agents still exist today; for a list of coloring agents, see below. Black glass was called obsidianus after obsidian stone. A second method is apparently to produce a black glass which, when held to the light, will show the true colour that this glass will give to another glass when used as a dye.

The Venetian ability to produce this superior form of glass resulted in a trade advantage over other glass producing lands. Murano’s reputation as a centre for glassmaking was born when the Venetian Republic, fearing fire might burn down the city’s mostly wood buildings, ordered glassmakers to move their foundries to Murano in 1291. Murano's glassmakers were soon the island’s most prominent citizens. Glassmakers were not allowed to leave the Republic. Many took a risk and set up glass furnaces in surrounding cities and as far afield as England and the Netherlands.

Glass art

Beginning in the late 20th century, glass started to become highly collectible as art. Works of art in glass can be seen in a variety of museums, including the Chrysler Museum, the Museum of Glass in Tacoma, the Metropolitan Museum of Art, the Toledo Museum of Art, and Corning Museum of Glass, in Corning, NY, which houses the world's largest collection of glass art and history, with more than 45,000 objects in its collection.

Several of the most common techniques for producing glass art include: blowing, kiln-casting, fusing, slumping, pate-de-verre, flame-working, hot-sculpting and cold-working. Cold work includes traditional stained glass work as well as other methods of shaping glass at room temperature. Glass can also be cut with a diamond saw, or copper wheels embedded with abrasives, and polished to give gleaming facets; the technique used in creating Waterford crystal . Art is sometimes etched into glass via the use of acid, caustic, or abrasive substances. Traditionally this was done after the glass was blown or cast. In the 1920s a new mould-etch process was invented, in which art was etched directly into the mould, so that each cast piece emerged from the mould with the image already on the surface of the glass. This reduced manufacturing costs and, combined with a wider use of colored glass, led to cheap glassware in the 1930s, which later became known as Depression glass. As the types of acids used in this process are extremely hazardous, abrasive methods have gained popularity.

Objects made out of glass include not only traditional objects such as vessels ( bowls, vases, bottles, and other containers), paperweights, marbles, beads, but an endless range of sculpture and installation art as well. Colored glass is often used, though sometimes the glass is painted, innumerable examples exist of the use of stained glass.

The Harvard Museum of Natural History has a collection of extremely detailed models of flowers made of painted glass. These were lampworked by Leopold Blaschka and his son Rudolph, who never revealed the method he used to make them. The Blaschka Glass Flowers are still an inspiration to glassblowers today.